What is a Hybrid Powerplant?

A hybrid powerplant generates electric power for high-performance electric aircraft using liquid fuels. There are parallels with the automotive industry wherein a hybrid-electric car combines the best aspects of electric motors, generators, engines, and liquid fuels to deliver a balance of performance and efficiency. The aerospace defense industry similarly values hybrids for the performance benefits, while the commercial market values lower operating costs and improved sustainability metrics.

VerdeGo Aero’s hybrid powerplants support dual-use applications to produce electric power for a variety of aircraft, such as unmanned military drones for cargo and ISR (intelligence, surveillance, and reconnaissance) missions, air taxis for short-range travel, and emergency medical evacuation helicopters.

![20240222_VerdeGo_Shoot--4[85]](https://verdegoaero.com/wp-content/uploads/20240222_VerdeGo_Shoot-485.png?_t=1721230402)

shadow

Engine

Control System

Generator

Power Electronics

Thermal Management System

An aircraft hybrid powerplant has five main components:

An ENGINE, either a turbine or a piston, to spin the generator.

THERMAL MANAGEMENT SYSTEMS to keep all the components cool

A GENERATOR/MOTOR that creates electric power and that can be used in some applications to drive a propeller, rotor, or gearbox

POWER ELECTRONICS that efficiently control the generator and convert the electric power from AC to DC, or from DC to AC

A CONTROL SYSTEM with both software and hardware that keeps all the components operating and to communicate with the aircraft's flight control computer.

Why Use a Hybrid Powerplant?

- When most people think about electric aircraft, they think about batteries. Batteries are great at delivering power in short bursts, but they are not good at storing enough energy for most aviation missions without adding so much weight that the aircraft can no longer fly. Batteries simply can’t store enough energy to give electric aircraft the range and endurance they need to meet FAA and EASA reserve requirements, or to enable demanding military missions in places where there will never be a charging station.

- Hybrid powerplants enable aircraft designers to design new aircraft that are electric-powered while using liquid fuel as the primary energy source to provide the range and endurance needed to meet the energy reserve regulations. Pound-for-pound, liquid fuel carries roughly 26 times the energy of the best battery packs available.

What about Sustainability?

If electric aircraft are all about sustainability, isn’t using liquid fuels a step in the wrong direction? Not necessarily. First, a well-designed hybrid-electric aircraft can be substantially more efficient than a conventional aircraft, while also being applicable to the flights that matter most in commercial transportation. An aircraft that is only capable of extremely short flights, doesn’t improve sustainability for the core air transportation market’s mid and long-range flights. Hybridization enables commercial aviation to achieve lower emissions and higher efficiency in a more practical way, delivering results decades before batteries can.

Secondly, Sustainable Aviation Fuels (SAF) have the potential to significantly reduce carbon emissions, even achieving net zero operation with the right manufacturing process. Using SAF, VerdeGo powerplants enable electric aircraft that are inherently more efficient to maintain new zero carbon emissions while delivering range and endurance not possible with batteries alone.

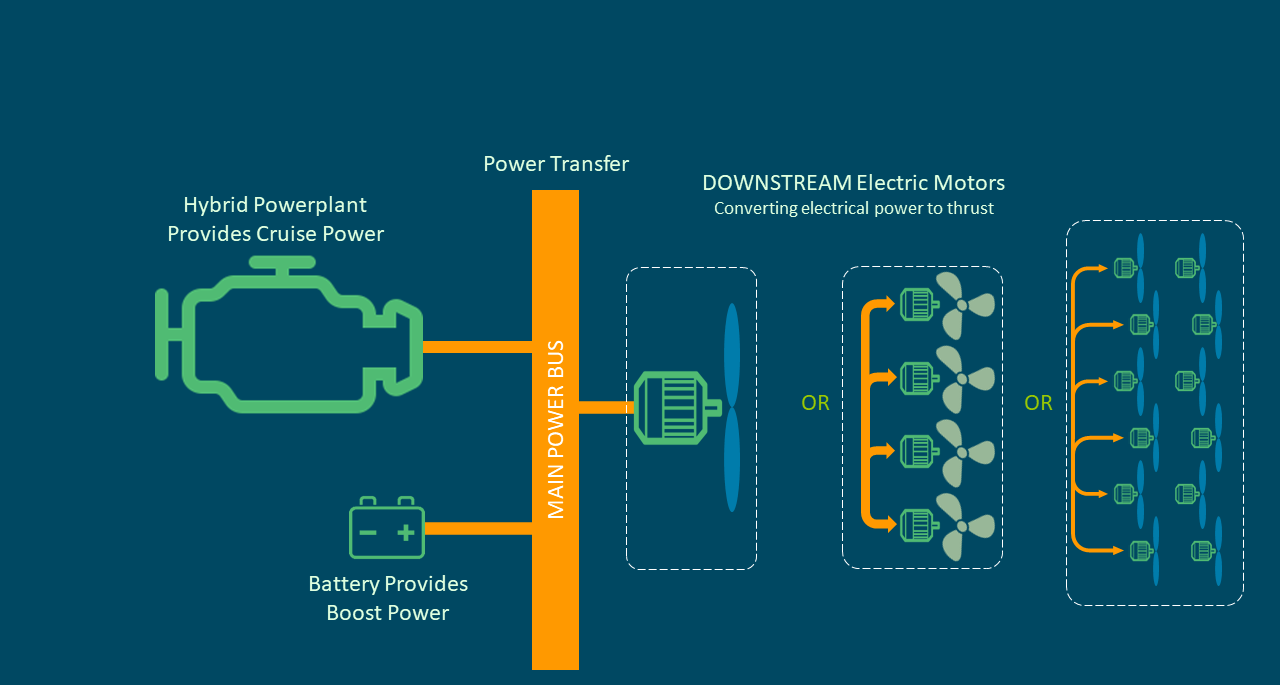

How is a hybrid powerplant used?

A hybrid powerplant is almost a replacement for a flight battery pack. While there are numerous different ways of applying hybrids, in a typical VTOL (vertical takeoff and landing) application, hybrid-electric powerplants are used to provide efficient cruise power while working in parallel with a smaller battery pack, which delivers short bursts of high power for takeoff, VTOL, and hover operations. It is often possible for a hybrid powerplant to increase range, payload, and speed simultaneously when applied to a battery-electric aircraft.

VerdeGo Aero’s hybrid powerplants enhance the performance, efficiency, and versatility of electric aircraft by replacing large, heavy battery packs with a more optimal aircraft powertrain. This translates into a lighter aircraft that frees up critical space and weight in scenarios like military resupply missions, emergency response and firefighting, and cost-effective regional air mobility. For example, a typical VTOL aircraft might be limited to flights of only dozens of miles with a 2,000 -pound battery onboard. However, a hybridized version of that aircraft can utilize a 550-pound VerdeGo VH4-T hybrid powerplant, a 250-pound battery, and 500 pounds of fuel — and have hundreds of miles of additional range, while also gaining 700 pounds of extra payload capacity to help carry more equipment or at least two more passengers.