VH-3 185 kW

What if you could have a 555 kW-hr battery pack with 1200 wh/kg energy density now and not decades in the future?

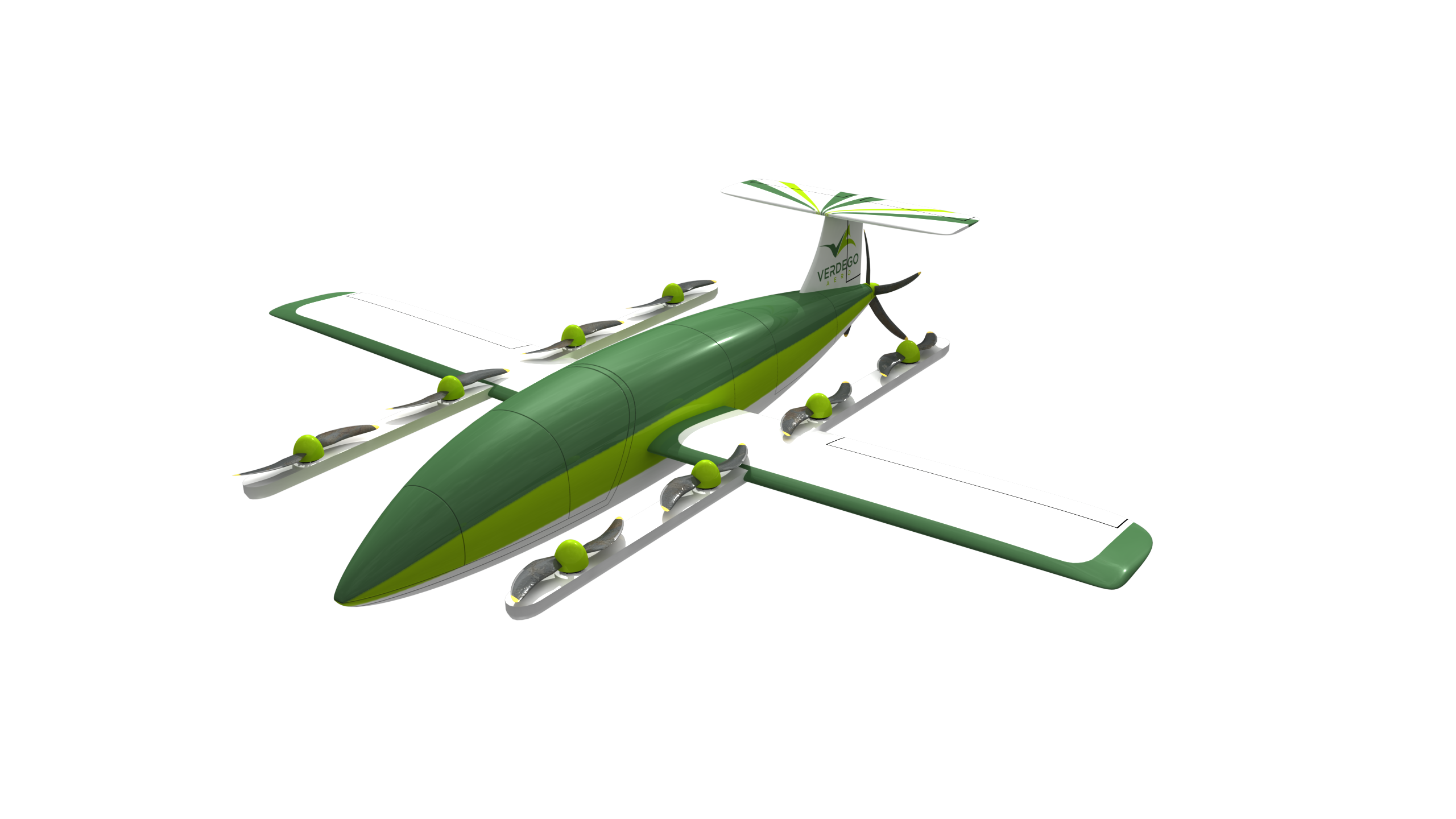

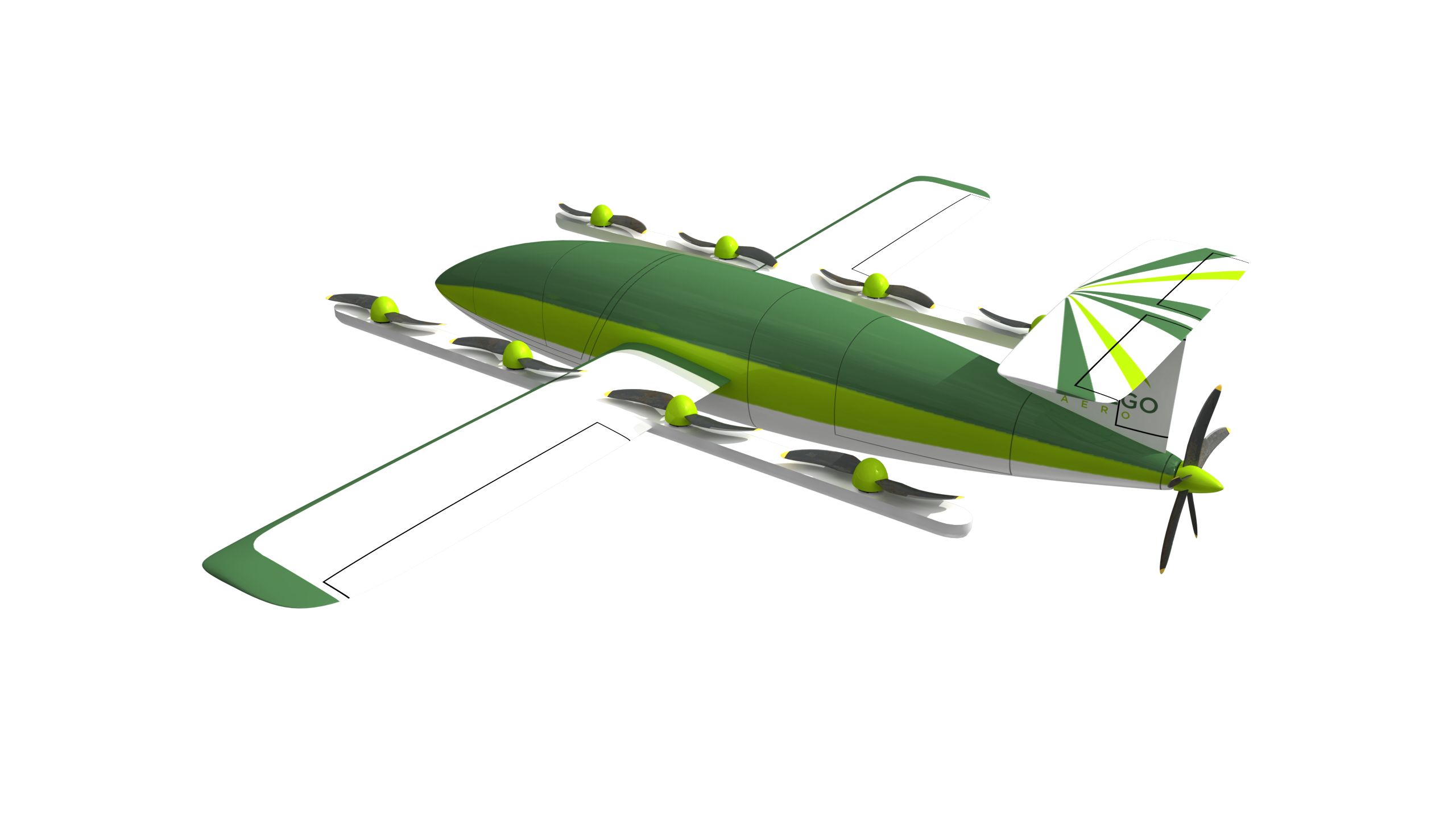

The VH-3-185 kW hybrid powerplant is a game-changer for commercial and military aviation, unlocking new mission capabilities across a range of applications, such as urban air mobility and regional cargo transport to tactical defense and unmanned aerial systems. Leveraging insights from two prior generations of VerdeGo Aero hybrid systems, the VH-3-185 sets the industry standard as the best piston-powered hybrid powerplant on the market. Our powerplant features patent-pending elements that make it more efficient, reliable, and flexible for applications in a wide array of market segments. The result is a next-generation powerplant providing 185 kW of continuous electrical power output in a 650 lb (277 kg) package with exceptional fuel efficiency of 0.37 lb/HP-hr (225 g/kW-hr).

With a focus on simplified electronics and engine operation, this powerplant is gaining traction with commercial and military customers, and its predecessor is already in flight testing in a crewed aircraft applying hybridization and distributed electric propulsion to achieve new levels of performance and efficiency.

Development of the VH-3 is supported by multiple U.S. Air Force and NASA programs involving multiple airframe applications across different markets. A trusted partner of the Air Force, VerdeGo was awarded a program to develop and test the first production-intent VH-3 prototype, accelerating its path toward operational deployment.

![20240222_VerdeGo_Shoot–4[85]](https://verdegoaero.com/wp-content/uploads/20240222_VerdeGo_Shoot-485.png)

shadow

Compatible with Jet-A, JPB, and Sustainable Aviation Fuel

Standard control interface and connection to main power bus

Hard points for mounting from above or below

Integrated air cooling for lightweight and high performance

Multiple power output modes

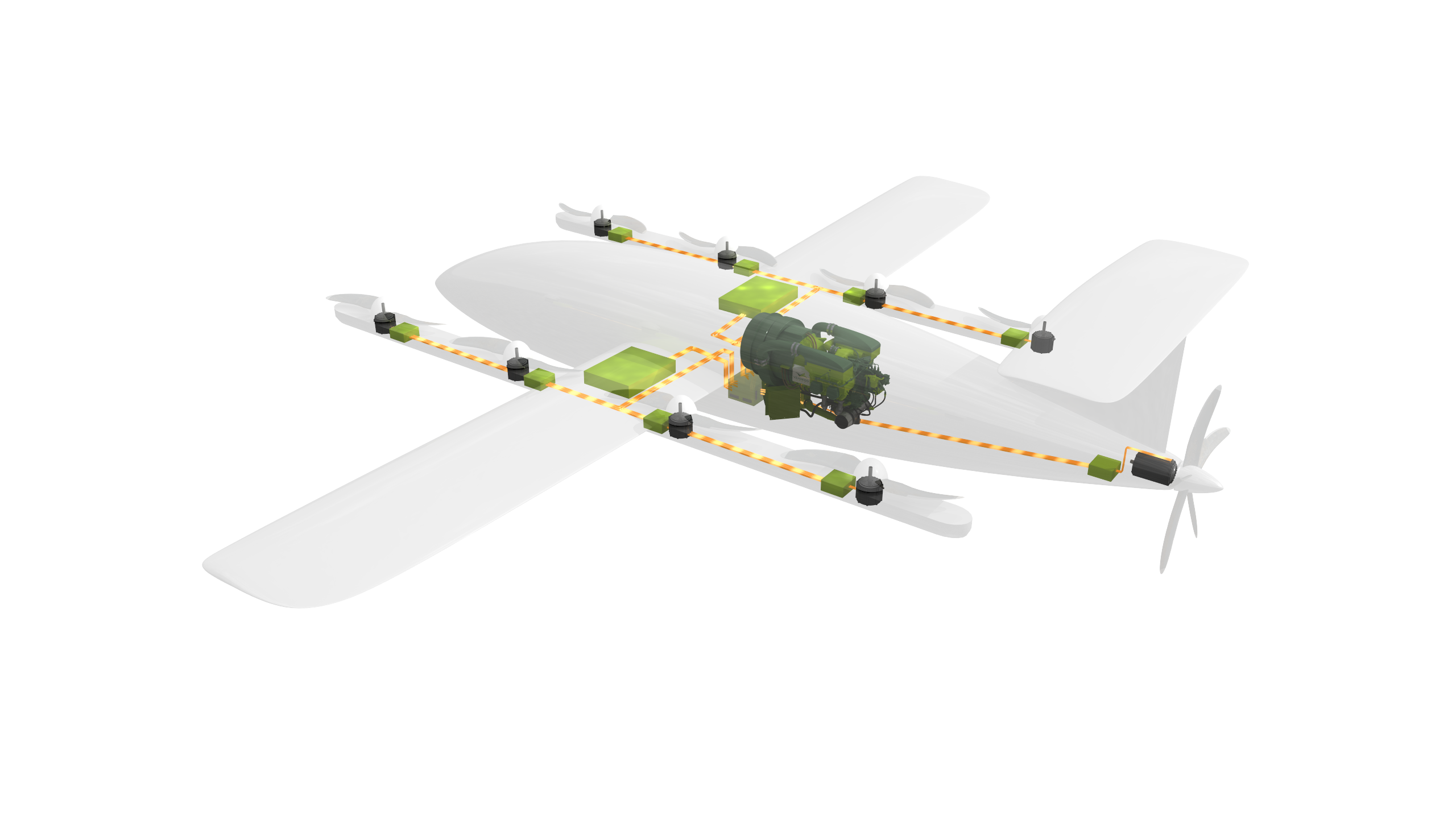

- VH4T Hybrid Powerplant offers series and/or parallel output

- Output power can be [blended/split/divided] between electrical power and shaft power, per customer needs

- Burst power from battery to boost shaft power up to 100%

Key Specifications and Capabilities

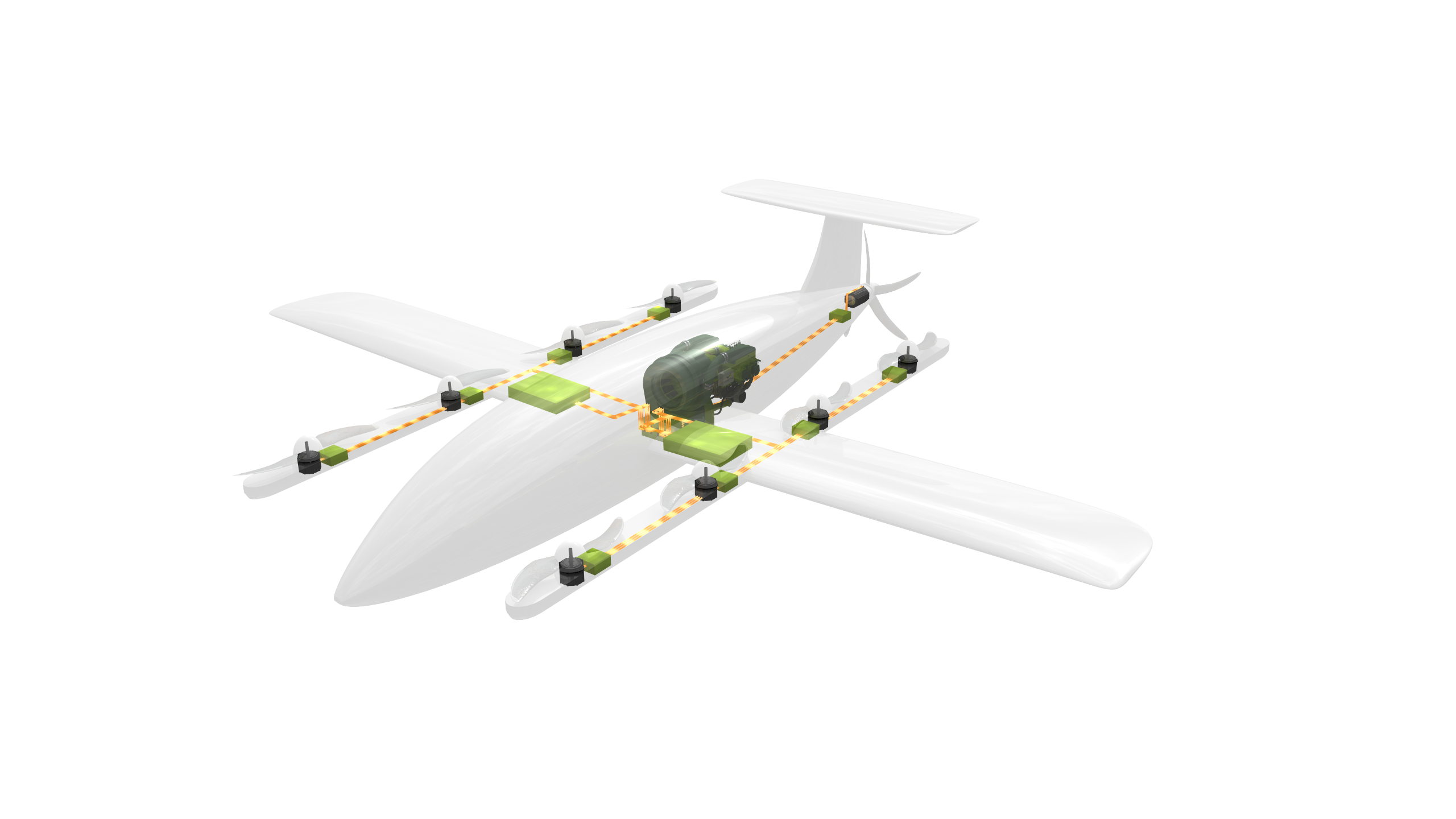

- Equivalent energy density of 600 – 1200 Wh/kg including the entire hybrid system and fuel

- 40% better fuel economy than turbines, with less noise

- Uses Jet-A or sustainable aviation fuel = zero new infrastructure required

- Self-contained system includes engine, generator, inverter, and thermal management using air cooling

- Delivers full power across a wide range of operating voltages – 600V – 800V DC

- Series parallel, or simultaneous series/parallel hybrid modes

Quiet, Efficient, and Economical Power for Electric Aircraft

Modular/Scalable

Use one powerplant for smaller vehicles, two or more for larger vehicles

Broadly Applicable

Suitable for UAM eVTOL, eSTOL, eCTOL

Quiet

Much quieter than turbines and turbine-hybrids

Lowest Direct Operating Costs

Compared to turbine-hybrids and battery-electric

Flexible

Multiple potential operating modes using optional thru-shaft: mechanical shaft power on/off, electrical power on/off, burst power from battery to boost mechanical shaft power

Batteries alone can't meet the mission?

5-7X higher energy density than batteries

Transformational range while meeting energy reserve requirements

Up to 12X faster refuel/recharge

More flights per day = more revenue

No charging infrastructure required

Turbine options too loud or too thirsty?

40% better fuel economy for lower DOC and carbon emissions

Available with noise mitigation to be 10-20dB lower than turbine systems

Built around a certified engine & air cooling, familiar aerospace technology